Kidde Australia appoints Tekin Industries as local NZ distributor for its portflio of gas suppression products.

“We are excited to have Kidde on board, especially the new IGS 400 series for clean agent systems. This is a game changer for the gas suppression market in NZ and we can’t wait to work with our clients, engineers, and consultants in bringing this solution to the market” (Aaron Willoughby – Director, Tekin Industries)

The new innovative IGS cylinder valve & release unit is the combination of +10 years of product development. The main benefit with the new IGS system is that during initial commissioning or scheduled maintenance, we now have the ability to simulate a full system discharge, without discharging the gas from the cylinders. Yes you read that correctly. End users, engineers, certifiers can witness the real time end to end operation of the system, both electrically, and mechanically.

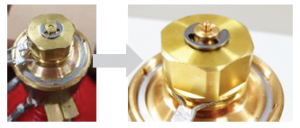

To achieve this, the transport cap (for new systems) or discharge hoses (for existing systems) are removed from the cylinders and replaced with the anti-recoil cap and tightned to 41Nm torque. The anti-recoil cap has a built-in discharge indicator (image below) which operates under pressure when the cylinder valve has been opened (simulating a discharge).

The cylinder valve opens when the quick connect actuation hose line is pressurised from the release unit (via simulated system sequence or manual operation) and then the discharge indicator on the anti-recoil cap will pop up as shown in the above image.

A pilot line bleed valve is installed in the unused actuation hose connection in the last cylinder which when manually operated relieves the pressure in the actuation line and the cylinder valves will subsequently close.

After verification that the cylinder valves have opened (from discharge indicators protruding), the system can now be returned to it’s normal state (reset any alarms / manual release), and the bleed valve can now be manually operated which will remove the pressure in the actuation line.

With no pressure in actuation line, the cylinder valve will then close, and the residual pressure built up under the anti-recoil cap will be released through a pin hole after just a few turns removing. The discharge indicator will then retract and it is now safe to completely remove the anti-recoil cap and install the discharge hose(s) to each cylinder valve. Place the system in automatic mode and the system is ready for normal operation.

Other benefits of the Kidde IGS suppression system include:

- No need for separate pilot cylinder. Up to 60 cylinders actuated with a single release unit mounted on primary cylinder.

- Pre-terminated factory quick connect electrical connections for gauges to supervise low pressure.

- Quick connect actuation hoses reduces installation time

- Pressure and flow regulating valve allows for Sch. 40 pipe for downstream pipework.

- Manifold is easier to reach with installation height now only 2.2m.

- Manifold pre-fabricated with pre-installed check valves ready for discharge hose connection.

The full range of Kidde Suppression Portfolio includes:

- Clean Agent Systems (Inert, CO2, FM200, Novec)

- WHDR Wet Chemical Kitchen Suppression

- Sentinel LS Wet Chem Heavy Vehicle / Machinery

- Sentinel DCS Dry Chem Heavy Vehicle / Machinery

- Reacton Vehicle / Cabinet Suppression

- ExxFire Non-Pressurized Suppression

Whether its a new system or an existing system, contact us for a free quote or to discuss how we can help.